Quality Shutter Frames Using the Latest Machines

HAYES SHUTTERS FACTORY TOUR

A Passion for Perfection

SHUTTER FRAME MACHINE

Since the frame is often the first thing people notice, it is extremely important that it is manufactured to the highest standards, but aesthetics aren’t the only reason for our passion for perfection!

An almost-perfect cut every time ensures your shutter frames are cut to your exact specifications, resulting in shutters that exactly fit the window opening. Frames on all Hayes Shutters are stronger than the competition’s frames due to the extreme accuracy of the cuts!

Our shutter frame machines use programmable tiger stops to ensure that the cuts and angles of the frame are accurate to 1/64th of an inch while negating the need for tape measures and, thus, human error. This ensures an almost flawless, perfect fit for every Hayes Shutter frame.

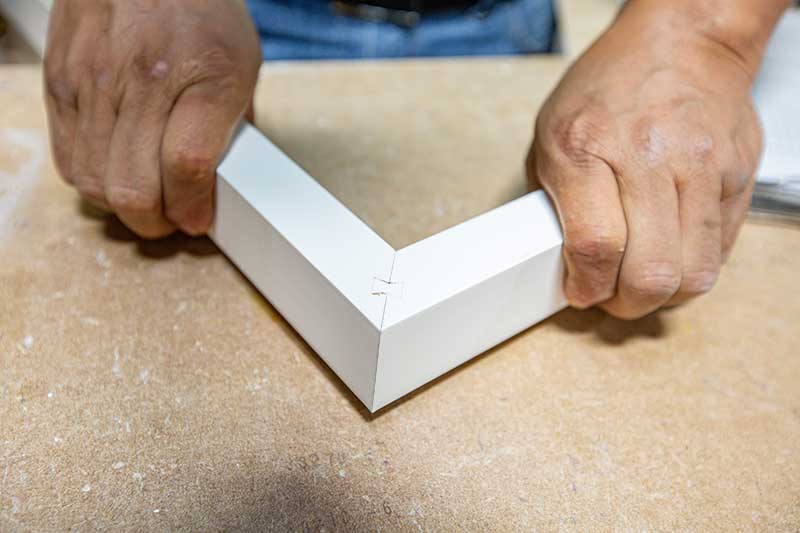

THE DOVETAIL KEY

In addition to the tiger stop, our frame machines use double miter saws, which cut an exact angle and insert a notch for a dovetail key with far more accuracy than a human could. Again, this ensures the dovetail key fits snugly, giving the frame extra durability and strength for a longer-lasting and better-looking Hayes Shutter!

THE BEST SHUTTERS START WITH THE BEST FRAMES

Computer-navigated machinery means precision cuts every time!

SHUTTER STILE MACHINE

To create that perfectly smooth open and close experience for your shutters, Hayes Shutters uses a stile machine to prep the stiles for the louvers at an accuracy of 1/64th of an inch. Accuracy is key as the rails must fit perfectly with the louvers and rails. An incorrect fit will cause the shutters to be difficult to open and close, thus causing undue wear and tear and reducing the life of the shutters.

SHUTTER RAIL SAW

Our rail saws cut the rails of the shutters to size using programmable tiger stops for the ultimate accuracy. Having an accurate cut means additional durability and beauty. Properly fitted rails mean that the shutter is easy to operate. The extreme accuracy of the cut also enhances the life of the shutter by preventing moisture from permeating the wood at the joints, which could lead to warping and cracking of the shutters.

SHUTTER RAIL MACHINE

Our rail machine is used for drilling the dowels in the rail and the mouse hole that is used as a place holder for the shutter push rods. The precise dowel cuts mean that the shutters can be closed completely to block out light and enhance privacy, and it also means that the shutters operate more smoothly.

If the cuts are not accurate enough, they can be too tight, creating unneeded resistance to the open-and-close process. Additionally, if the fit is too loose, the shutters won’t stay closed, leading to an unhappy homeowner. Both circumstances lead to additional wear and tear on the shutters, reducing the longevity of the shutters.

ACCURACY IS KEY TO SHUTTER QUALITY

Hayes Shutters are built to last and are backed by a lifetime warranty!

THE LOUVER CUTTING MACHINE

Our louver cutting machine can cut the louvers to within 1/64th of an inch in a variety of sizes while ensuring uniformity and precision. The advanced technology means that each shutter produced will maintain that perfect gap between the louver and the stile, and will be a beautiful addition for any window it will accent. It also enhances the light filtering effect of the shutters by providing more precise gaps.

THE LOUVER DRILLING STAPLER

The louver drilling stapler uses the latest in shutter technology to staple the louvers to the push rod. Because of the automation, human error is eliminated, allowing the louver drilling stapler to ensure the exact placement of the rod to the louvers every time. This makes the shutters easy to operate while providing consistent spacing for each louver.

This perfect spacing maximizes the light-filtering capability and privacy provided by the shutters. Louvers that are too far apart let in too much light and louvers that are too close together are difficult to open and close. When this is the case, the shutters will not last as long as they should due to parts rubbing against one another and breaking down.

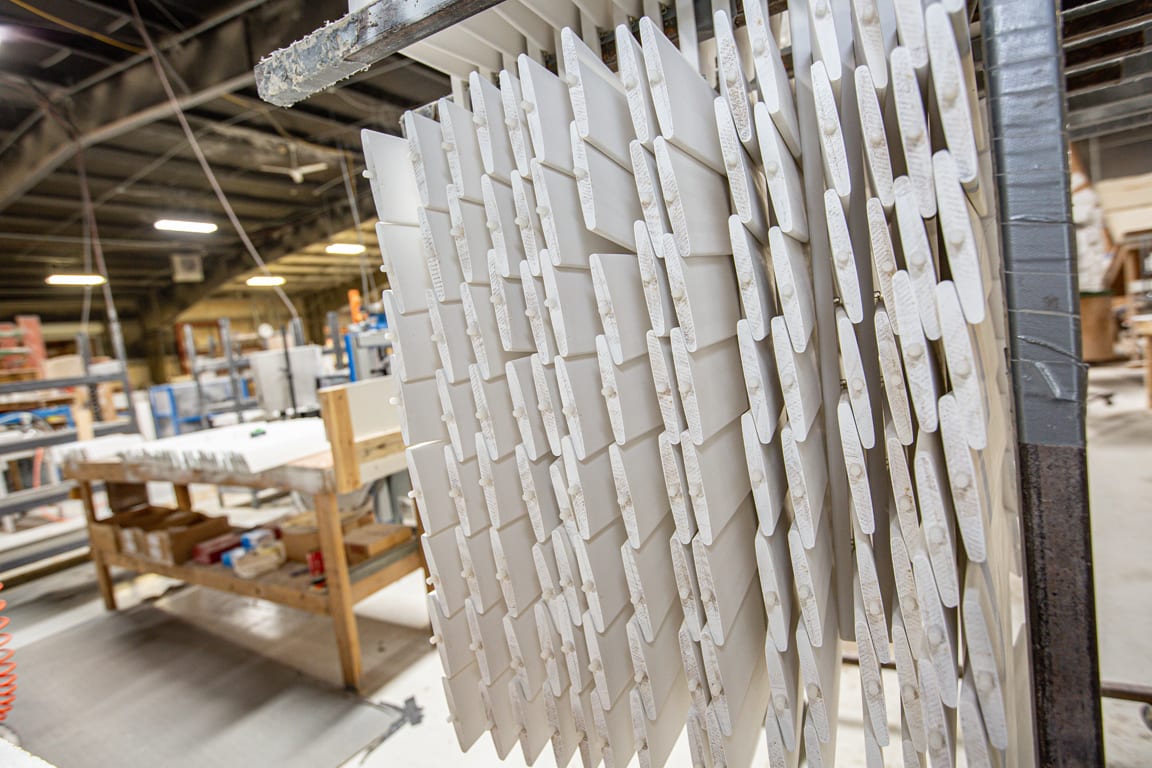

LOUVERS READY FOR ASSEMBLY

Once the louvers have been cut, drilled, and stapled to the push rod, they are hung where they are available for assembly with the frames and rails when it is time to construct the finished product.

ULTRA-FAST SHUTTER DELIVERY

Better technology means faster delivery with fewer errors!

FINAL SHUTTER ASSEMBLY

Once the shutter rails, frames, and louvers are ready, they are carefully pieced together and clamped with industrial strength glue to create a gorgeous finished product. Hayes uses the highest quality glue to ensure the longevity of our shutters.

PERFECT SHUTTERS READY TO SHIP

Hayes Shutters is able to turn shutters around more quickly than its competition for many reasons. First, they always have plenty of materials on hand, and second, their use of the latest in technology means that they have very little waste.

Eliminating errors from the manufacturing process means that their shutters are perfect the first time. In fact, Hayes Shutters can ship in as little as two to four weeks from the receipt of an order.